One question that is often addressed when setting up a component database is how to support common components from various manufacturers. A good example is a resistor. Given certain parameters (1.0 kOhm, 5%, SMD 0603, 1/10 watt), there are several manufacturers that make equivalent parts. We call these “generics”. An engineer would choose a generic, but a purchasing person would choose a specific manufacturer that is in stock at some vendor for the lowest price.

Aligni is somewhat ambivalent on the subject. You are free to setup a “Generic” manufacturer or even a “Generic Resistor” manufacturer and then create components within that manufacturer. You would then need to come up with some sort of part numbering scheme for the manufacturer’s part number.

When you hand over a bill of materials to a contract manufacturer to assemble your product, they may want to see real manufacturers and real parts rather than generics. This removes the burden from them of selecting the right part and, more importantly, any liability for choosing an incompatible device they thought would be suitable.

Part Alternates

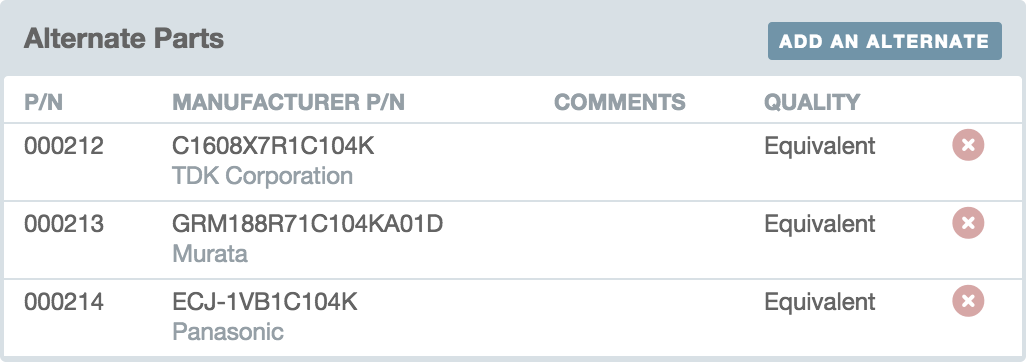

Aligni allows you to list alternates for any part in your database. These alternates are listed on the part details page. You can then choose from among these alternates for any part in a part list. Aligni provides two ways to define the relationship between similar parts:

- Equivalent – This means that two parts are suitable for any installation. They have identical parameters and differ only by manufacturer.

- Alternate – This means that two parts are similar, but substitution requires consideration. For example, a 6.3v capacitor may be an alternate for a 10v capacitor, but the design should be considered before making the substitution.

As shown in the diagram above, the Generic part will list the Yageo, Vishay, and Panasonic parts as equivalents. The Yageo part lists the Vishay and Panasonic parts as alternates because the Yageo part is a higher tolerance component. Substituting a lower tolerance part will require design consideration.

When Generics are part of your database, engineers will typically choose a generic component when one is available. Purchasing will then have flexibility to choose among the available equivalents before building assemblies.

When you create a part alternate relationship, the relationship is unidirectional. You can optionally create the “reverse relationship” to establish a corresponding relationship in the opposite direction.

An Argument Against Generics

What’s our opinion on the matter? We don’t recommend using generics. Here are a few reasons why. For the sake of this discussion, let’s consider a “generic” 470uF, 35v, electrolytic capacitor.

Design Specification

Searching for this capacitor in DigiKey’s catalog yields more choices: 4 choices of ESR, 2 choices of lead spacing, 4 temperature ranges, and 4 package choices. To accurately define the capacitor for a particular design, you’ll want to at least further specify a few parameters. It can become cumbersome to determine and specify the minimal set for hundreds of parts.

Creating Part Numbers

Inevitably, you will need to create a part number for a generic. This part number will probably need to include most of the parameters in some form. Coming up with a consistent format that is “future-proof” is frustrating and has already been done by most manufacturers of the parts. For most parts, manufacturers have detailed descriptions of part number encodings. Why repeat this work?

In the end, it may make the most sense just to number generic parts sequentially and provide detailed descriptions of each part or add several custom parameters.

Which of these is more useful on a bill of materials?

- Generic – 02348291

- Generic – CAP_470_AXIAL_C_330ESR

- Panasonic – ECA-1VM471

The second is mildly appealing because some of the part description is contained in the part number. But in consideration of the effort involved in just naming this part, what has been gained?

Purchasing and Production

Using a generic manufacturer causes a bit more work when the project moves to purchasing and production. Someone needs to go through and select parts from the available inventory, either the designers or the manufacturers, then purchase parts not in inventory. This someone is often someone not familiar with the design objectives and may end up making poor decisions. Why not just have a part chosen ahead of time? What has the selection of a generic gained?

“But really, ANY resistor will do!”

It may be uncomfortable for an engineer to choose a particular manufacturer when she knows that any will do for a given resistor. But since Aligni supports the concept of equivalent parts (i.e. those that are perfectly suited for substitution), this discomfort is probably ill-founded. The decision to label two parts as equivalent should be done such that either part may be chosen in any circumstance.

If any resistor will do, why not just pick a specific one? If you need to make a substitution later on, at least there is a very clear reference that doesn’t require revisiting the design.